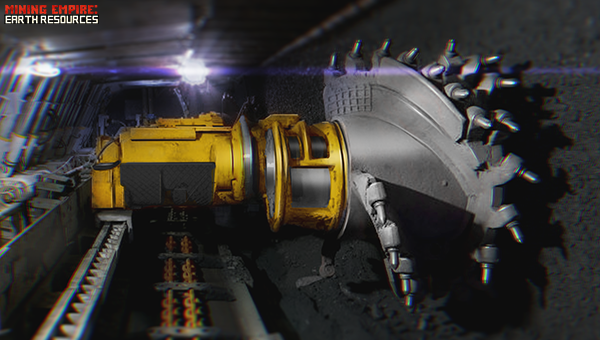

Sneak Peek #11 - THE SHEARER

The shearer is a combined mining machine that mechanizes technological operations in the longwall, separating the mineral from the reservoir mass and loading it onto a transport machine.

The main functional elements of modern shearers are: the executive body, which destroys (separates the mineral from the reservoir mass) and loads it on the bottomhole conveyor; hydro insert and one or two feeders to move the combine along the face room; drive consisting of one or two electric motors, main (right and left) and rotary gearboxes that transmit a torque from the engines to the shafts of the executive bodies.

On the rotary gearboxes and augers there is a nozzle irrigation system. The main gearboxes are connected to the motor housing by bolts and studs.

The shearers are classified by: the power and angles of incidence of removable reservoirs; the width of the executive body; the design of the executive body and the supply system - by type of energy to drive combines.

The executive bodies of the shearers in design can be: auger, drum, crown, disk, chain and combined.

The following basic requirements are imposed on executive bodies:

- ensuring the highest possible performance under given mining-geological and mining conditions;

- destruction of minerals with minimal energy intensity and degree of grinding;

- implementation of the unloading of minerals from the work area of the executive body and loading it onto the haul truck (when the shearer is working on flat and inclined surfaces);

- the possibility of infinitely variable height adjustment (according to the thickness of the extracted mineral reservoir);

- high mechanical efficiency, reliability and durability.